The aircraft is now in the process of being given its new paint scheme, with much of the old paint now removed. Once the painting is complete, the aircraft will be returned for some final checks next month, ahead of its anticipated delivery to the University in April. Photos are shown below of the preparation and initial paint removal.

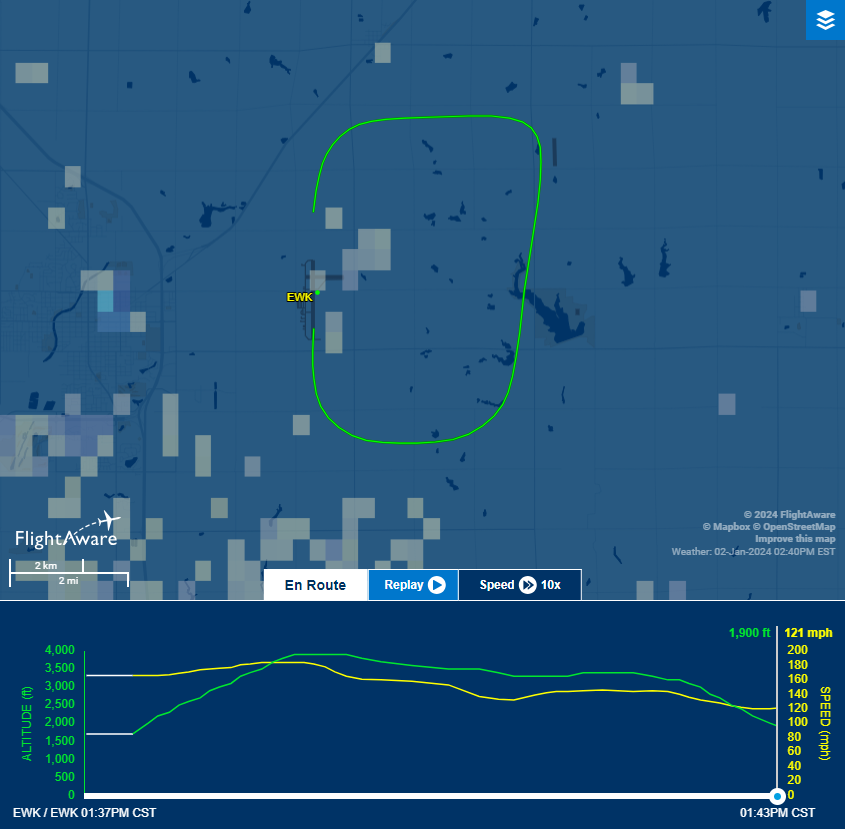

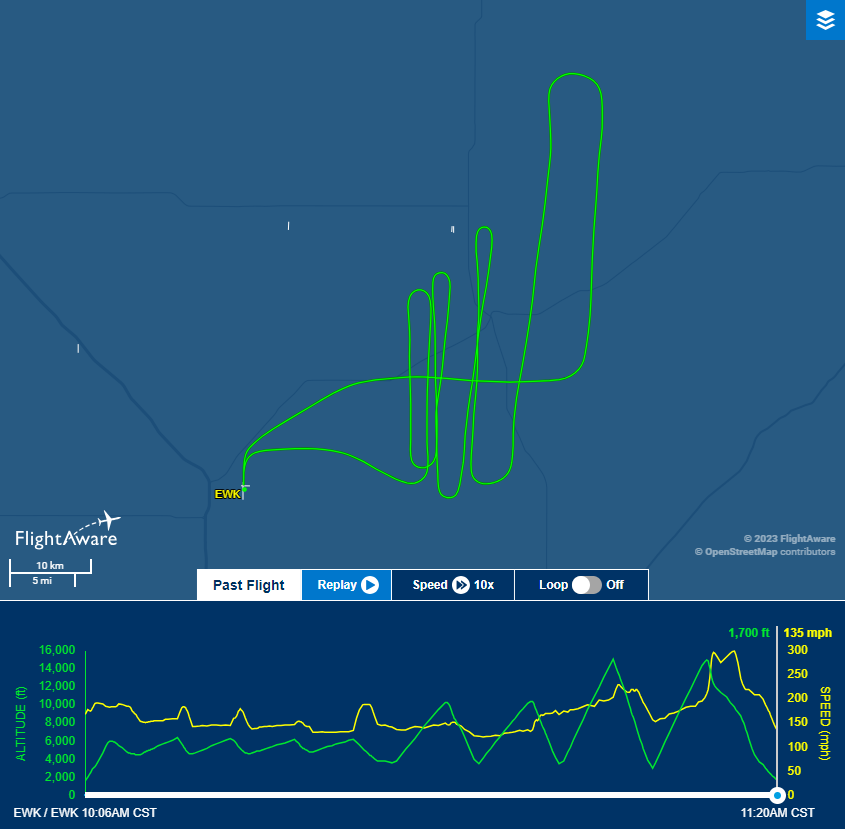

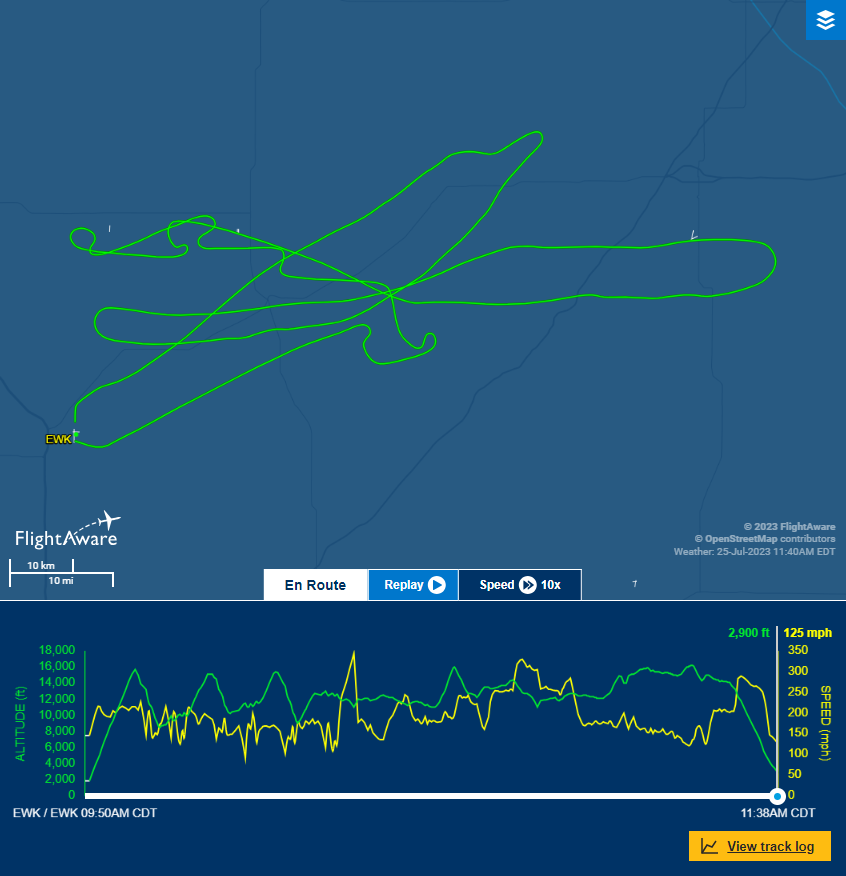

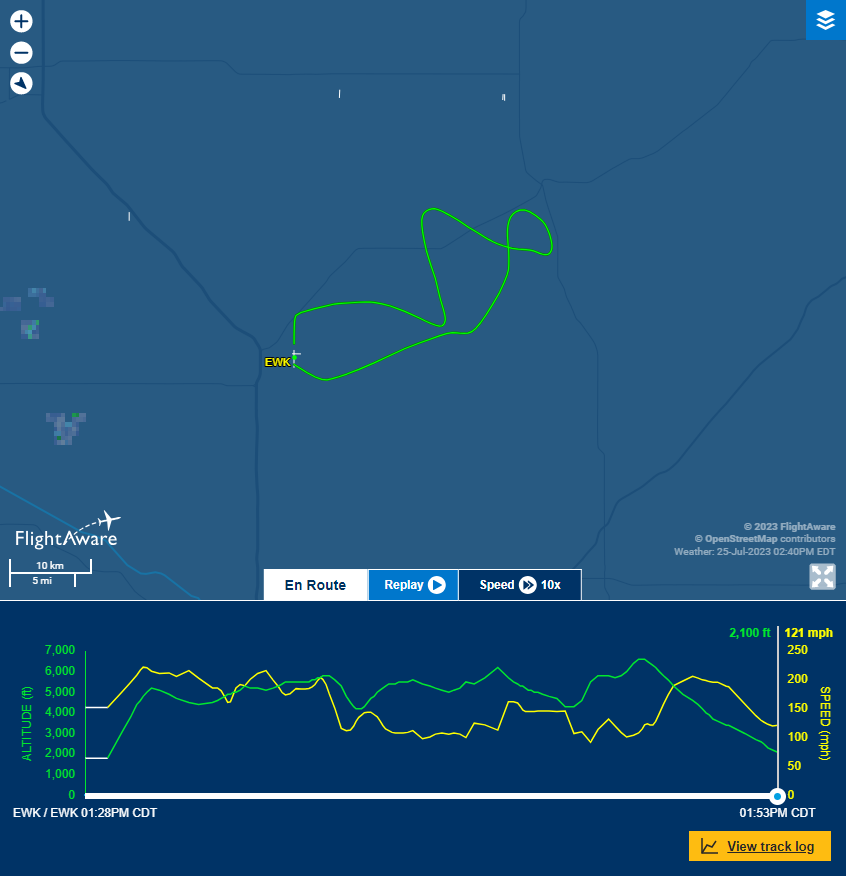

Flight testing for the new King Air was successfully completed in early January, doing a variety of flights characterizing aircraft performance under various loads, as well as measuring noise characteristics of airport overflights. The aircraft is now being prepared to receive its custom paint scheme, in preparation for an expected delivery to the University. Subsequently, the UWKA facility crew will begin additional in-house work on the King Air to complete its preparations for research readiness. The custom paint scheme is shown below, along with several of the final flight tracks testing various performance characteristics.

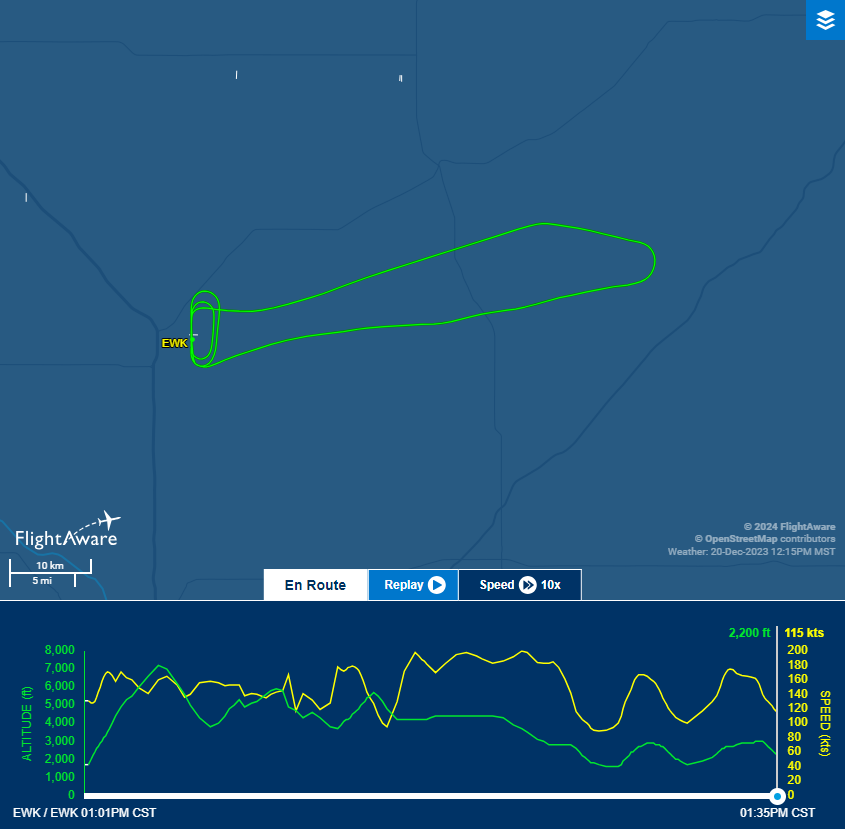

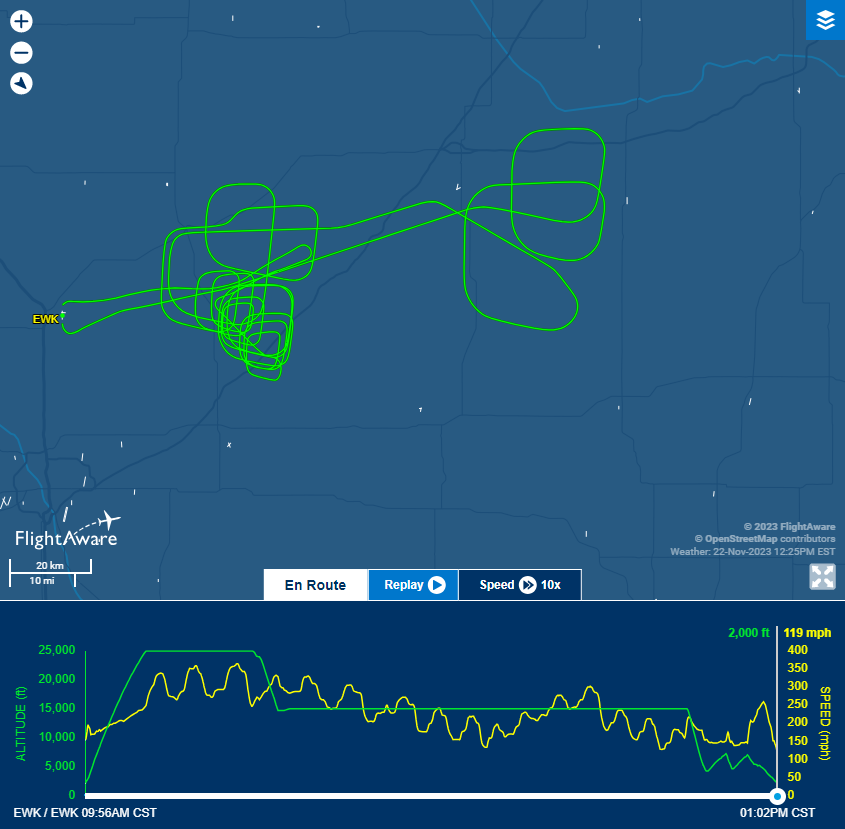

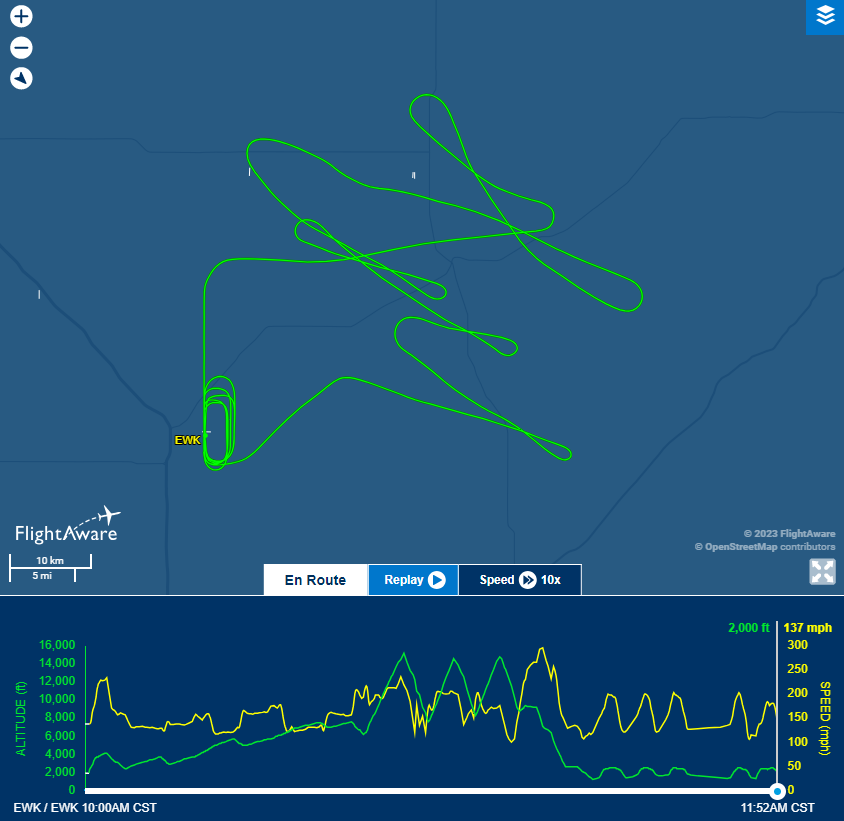

Flight testing assessing the performance penalty of exterior instrument installations proceeded in November and December. Flights took place using a variety of simulated payloads under a range of flight conditions, with a majority of flight testing now completed. Several example flight tracks are shown below.

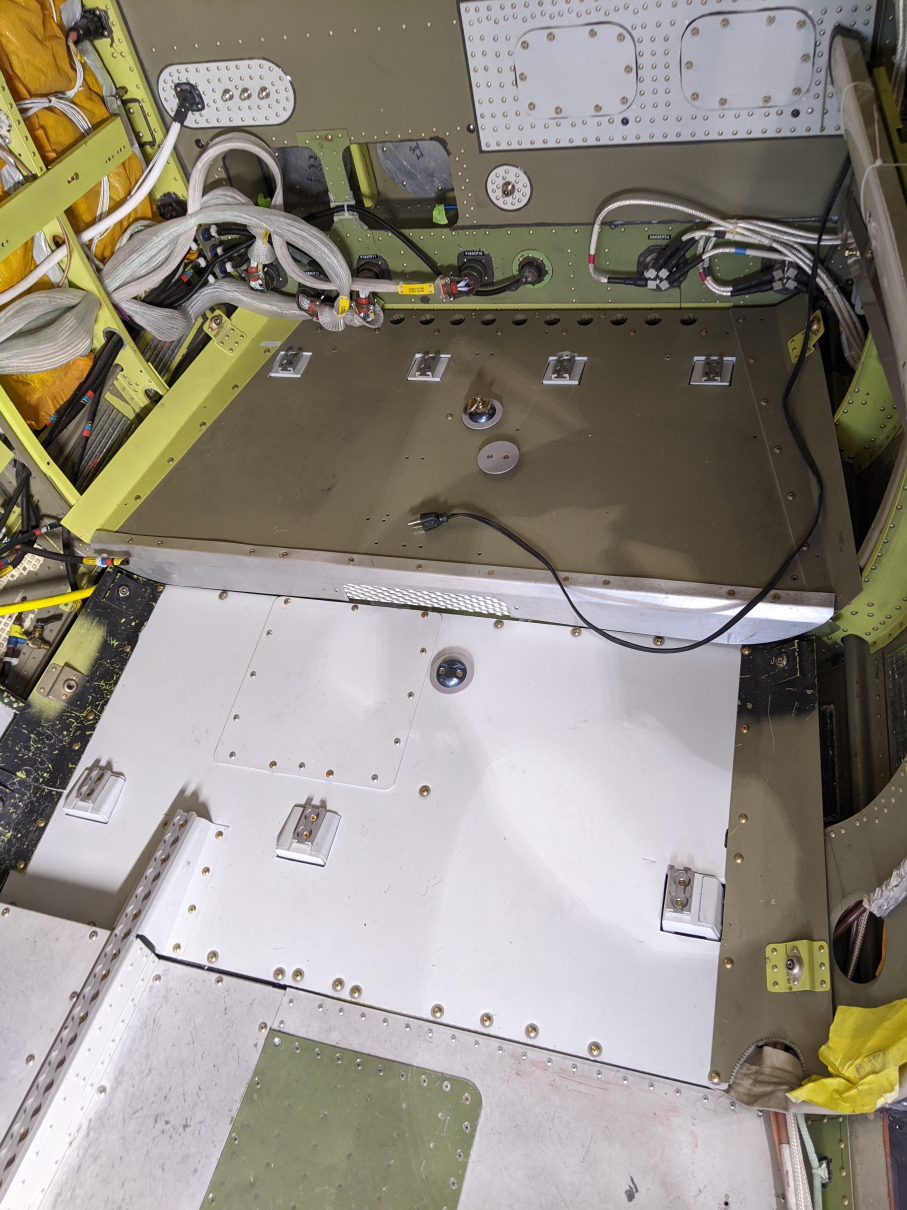

Work has continued to finalize the King Air’s interior modifications, with the transition from the original passenger aircraft configuration to a research mission interior now complete. Examples of the modified research interior configuration are shown below.

The next step forward will be the completion of drag testing in flight, with the aircraft now ready to proceed with flight testing. This will identify the performance penalty of instruments installed on the aircraft’s exterior, using various shapes constructed out of aluminum and 3D printed plastic. These are mounted outside the aircraft to simulate the sizes and characteristics of the actual instruments, with 8-12 configurations designed to simulate the effects of various instrument payloads. Examples are shown below for several external mounting points, along with some views of the full installation.

Work has continued to proceed on the interior of the aircraft, including tasks related to the research electrical system. This takes place in preparation for the next set of flight tests, which measures the impact to the aircraft's performance of various research equipment that may be installed on its exterior. This provides valuable information for identifying the aircraft's capabilities with specific requested instrument payloads when it comes online for research flights.

Additionally, the color scheme for the aircraft has been finalized. This custom scheme will replace its current paint and display the aircraft's affiliation with the University of Wyoming and the National Science Foundation, as well as echoing the color schemes used by the facility's original research King Air.

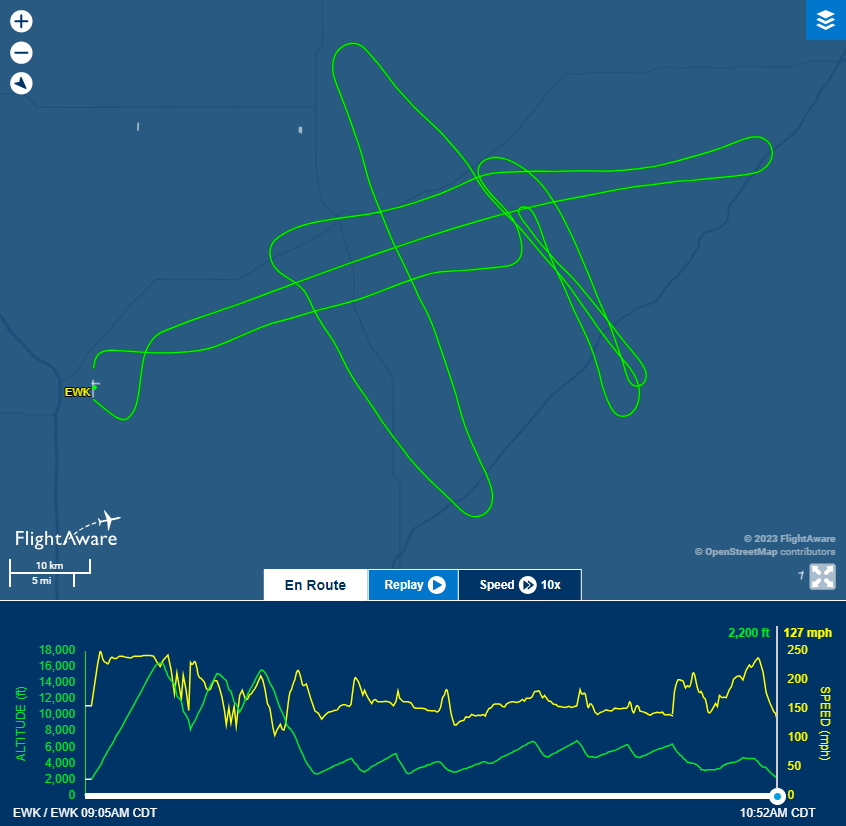

In early July, the modified King Air completed a major milestone in the certification process, successfully passing its initial commuter category flight test. This is a precursor to the FAA testing that will be required to certify the aircraft for use in its research role with the University of Wyoming. The photos below show the external configuration for testing, with structural modifications complete but no equipment installed, along with the track and details for the test flight courtesy of FlightAware.

Flight testing continued successfully, focusing on performance aspects such as flight characteristics under various center-of-gravity configurations. Subsequently, the interior of the aircraft will be returned to its basic research configuration to prepare for FAA flight testing.

Work continued in April and May, focusing on additional airframe alterations to help support the aircraft's instrumentation and communication capabilities. These included modifications to the aircraft's Traffic Collision Avoidance System (TCAS) antenna position to account for research equipment installation needs, updates to the air conditioning system to increase its capability to maintain cool instrument temperatures, and changes to the aircraft's passenger baggage compartment to support an instrument rack and operator's seat. These updates are taking place prior to the next phase of the aircraft's development process, a sequence of flight tests to evaluate its capabilities.

Much of the ongoing work for the next-generation King Air now involves details necessary for the aircraft's certification ahead of its delivery to the University of Wyoming. Several projects involving modification of the airframe are still in progress as well. These include modifications to the main landing gear doors, as well as fabrication and installation of parts for the zenith instrumentation ports and the downward-facing camera port.

Installation of the Nose Boom and Extended Nose Assembly began in January and continued into February, following completion of developing the tooling necessary for the build. The Nose Boom will be used to mount a Rosemount 858 Air Data Probe (for winds and turbulence measurements). The extended nose will provide several locations for mounting instruments. There will be a total of 5 instrument pads that are fully configurable with sufficient space inside the nose to mount additional instrument electronics.

With most of the big modification designs completed or near completion, attention is turning towards some of the smaller design projects. In November Avcon presented their conceptual design for the AVAPS dropsonde port (see images below) which will be located near the rear of the fuselage. The design is expected to be finalized in late December or January.

UW provided comments to Avcon regarding the selected ODA (Organization Delegation Authorization) who will be completing the certification for the research configuration. A kickoff meeting between all 3 groups was held in November, since then work has focused on the development of the Project-Specific Certification Plan (PSCP). We are targeting submission of the PSCP by the end of March.

Avcon Industries has completed the tooling necessary to fabricate the extended nose

for the new aircraft. The tooling is necessary to ensure the complex angles designed

for the nose are repeatable. The tooling is based around a salvaged nose from a B300

aircraft (see pictures above). Nose fabrication is scheduled to be complete in late

December with installation beginning in January.

With most of the big modification designs completed or near completion, attention

is turning towards some of the smaller design projects. In November Avcon presented

their conceptual design for the AVAPS dropsonde port (see images above) which will

be located near the rear of the fuselage. The design is expected to be finalized in

late December or January.

Several flight tests were completed in November for the wing pylons to show compliance with noise requirements and any impact on different modes of flight. The flight test results are expected to be complete in December and will be used for baseline flight characteristics that are needed prior to the installation of the extended nose, to begin in January.

Avcon Industries began work on fabrication of the extended nose and nose boom. Avcon acquired a nose section from another B300 and is using that nose section to develop tooling for the extended nose fabrication. Installation is expected to begin in early December, following the completion of baseline flight tests currently scheduled for mid-November

A familiarization meeting was held at the UWYO flight facility in early October. In attendance were the Avcon engineering and management teams and administrators from AERO DC, the ODA that is under contract to Avcon to develop and certify the research STC. The research certification project officially began with the familiarization meeting, laying out the certification path and the initial development of the PSCP (Project Specific Certification Plan) that is targeted for FAA submission by the end of this year.

Following the release of a new baseline schedule from Avcon that i

September 30 marked the completion of the second year of the NSF-funded MSRI project for the development of the Next Generation UWKA. Major accomplishments during the first two years include: acquisition of the low-hour 2013 King Air 350i that serves as the baseline aircraft; upgrade to larger PT-67A engines, upgrades to Garmin G1000 Avionics, upgrades to allow for larger takeoff weight, completion of major design work for extended nose with nose-boom and underwing pylons; installation of underwing pylons and two large nadir ports for radar and lidar, and completion of conceptual design for all other major fuselage modifications.

In early September, the UWYO team conducted a site visit to Avcon, the primary contractor for aircraft modifications and certification. The site visit included discussion on remaining major design work to be completed, acceptance of completed installations, and pathway towards full research certification.

Flight testing was completed on the under-wing pylons in July. Pylons on each wing

were loaded with weighted ‘PMS-style’ instrument canisters and flight tested for performance

and flutter. These are expected the be the last tests needed for completion of the

certification of the pylons.

Initial design work on the mission electrical system is nearing completion. During

this ‘conceptual design phase’, UW and Avcon engineers have been working towards a

mission electrical system capable of delivering 400 Amps of 28 Volt DC power for the

research electrical system on the new King Air. The Preliminary Design Review for

this system is scheduled for early August.

Preliminary design work is nearing completion on the zenith ports for the new King Air. The ports consist of 5 small (3”X5”) ‘multi-use’ ports for various instrumentation and 2 large (14” diameter) ports for use with the Wyoming Cloud Radar. Preliminary Design Reviews for the zenith ports is expected in August.

The first major research modification was completed this month. The installation of the two major nadir ports were completed in June. These ports will be primarily used for the Wyoming Cloud Radar and the Raman and Doppler Lidars.

The under-wing pylons and wing wiring channels were completed and installed on the aircraft. In late June, ground vibration testing (GVT) was completed—the first step for the certification testing—with PMS-style canisters mounted on the pylons. Flight testing is scheduled for July.

Work continues towards finalizing the upper crown layout, which includes the location of all ports and hardpoints on the top of the fuselage and the locations of antennas (with ‘keep out’ areas).

Work continues on the installation of nadir ports.

The design of the wing pylons has been finalized and approved by the UW. Each pylon

will be capable of carrying 3 PMS-style canisters, increasing by 50% the capability

compared to the current UWKA.

The STC for underwing hardpoints, to which will be attached the instrument pylons, has been approved by the FAA. These hardpoints are located near the wingtip, which is a significant improvement over other STCs for wing hardpoints owned by other companies located more inboard, nearer the engines, on other King Air 350 aircraft.

The design of the nose extension and nose boom has been finalized and approved by

UW. The nose extension is significantly more capable (in terms of weight/volume) than

the existing nose extension on the current UWKA. Manufacture of the nose extension

will begin in June, with installation scheduled to begin in mid- to late-summer.

The conceptual design for two large zenith ports that will be used by the Wyoming

Cloud Radar is complete. Completion of the conceptual design is a critical milestone

so that work may begin on the development of the WCR upgrade.

The first major research modification has begun with two large holes (~20”) cut in the bottom of the fuselage. The nadir ports are existing STCs (already certified); the ports will be used for the Wyoming Cloud Radar and the Raman and Doppler Lidars, and will also be available for other downward looking remote sensors.