Contact Us

Institutional Communications

Bureau of Mines Building, Room 137

Laramie, WY 82071

Phone: (307) 766-2929

Email: cbaldwin@uwyo.edu

Manufacturing in the Space Age

Published May 16, 2023

January 8, 2021

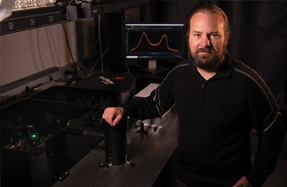

Associate Professor Patrick Johnson and team are researching thin films of single

material that can be treated with a low-power laser to manufacture, replace and upgrade

devices in space.

UW professor Patrick Johnson and colleagues lead a NASA grant for machine learning materials and manufacturing methods for space.

By Caitlyn Spradley

As humans push further into space exploration, a need arises to develop flexible electronics and in-space manufacturing. Patrick Johnson, an associate professor in the Department of Chemical Engineering, is one of three University of Wyoming College of Engineering and Applied Science professors awarded a $750,000 NASA grant to lead a team of researchers in developing machine learning materials and manufacturing methods for space.

In addition to Johnson, the UW team includes Assistant Professor Lars Kotthoff, computer science, and Assistant Professor Dilpuneet Aidhy, mechanical and energy systems engineering.

The three-year grant for their project, titled “Artificially Intelligent Manufacturing of Flexible Electronics,” was funded through NASA’s Established Program to Stimulate Competitive Research (EPSCoR).

“The limitations to the kind of objects that can be made in space with additive manufacturing techniques are an important and vexing problem, and NASA has put a high priority on identifying solutions to this challenge,” Johnson says.

According to Johnson, game-changing developments from NASA partner Made In Space will allow the manufacturing of parts required for space exploration. These developments include VULCAN, a 3D printer that will be able to use metals and polymers for additive manufacturing, and Archinaut, a system to manufacture large-scale parts that cannot be transported into space—including heat shields and antennae in space during a mission.

However, while both methods hold a lot of promise, they come with a number of drawbacks, the researchers say.

“Made In Space’s approach cannot manufacture electronics from scratch but only integrate existing components,” Johnson says. “Inkjet printing relies on different materials, namely different inks and the substrates, to be available. The size of the manufactured circuit is limited to the size of the inkjet printer. Both techniques require relatively large amounts of power over relatively long periods of time to operate.”

Johnson’s team in the Artificially Intelligent Manufacturing (AIM) center in the UW College of Engineering and Applied Science has developed a complementary technique that does not suffer from these drawbacks.

“Our team is researching thin films of a single material that can be treated with a low-power laser to manufacture circuits and replace or upgrade devices,” he says. “This technique can be used to create submicron-scale conductive lines in carbon materials of arbitrary dimensions and consumes less power than 3D and inkjet printing techniques.”

The researchers’ efforts look to merge synergistic expertise in materials development and computer science for the development of powerful methods to design and model the behavior of advanced materials and the manufacture of advanced devices.

Johnson says that the grant will continue to foster interdisciplinary research among chemical engineering, mechanical engineering and computer science, giving UW undergraduate and graduate students opportunities to apply machine learning to advance laser manufacturing and computational materials science research.

“The grant enables the production of advanced materials and training of machine learning scientists in advanced manufacturing processes, which is especially important in the current economic climate,” he adds. “This grant will help facilitate Wyoming’s transition to a high-tech state and attract investment beyond its traditional industries.”

Cameron Wright, interim dean of the College of Engineering and Applied Science, praises Johnson and his colleagues for securing the NASA grant.

“This project will have direct applicability to the future of NASA’s space exploration and will support both our educational mission and economic development in Wyoming. It’s really a win-win,” Wright says.

Johnson holds a B.S. in chemical engineering from Lehigh University, an M.E. in biomedical engineering from the University of Virginia and a Ph.D. in chemical engineering from Columbia University. He specializes in biointerfaces, nanomaterials, biosensors and biomaterials.

The team of collaborators for NASA project includes Meyya Meyyappan, chief scientist for exploration technology, and Jessica Koehne, a scientist in the Center for Nanotechnology, both at the NASA Ames Research Center.

Contact Us

Institutional Communications

Bureau of Mines Building, Room 137

Laramie, WY 82071

Phone: (307) 766-2929

Email: cbaldwin@uwyo.edu