|

IECM 13.1 User Manual > Modules Included with the IECM > Pulverized Coal (PC) Plant > GET RESULTS > TSP Control > Fabric Filter > Fabric Filter Diagram |

|

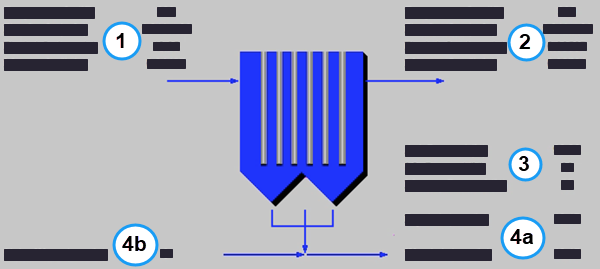

The Fabric Filter Diagram result screen shows the major flows into and out of the Fabric Filter particulate control technology. This screen also applies to the secondary fabric filter used in the Oxyfuel Low S configuration:

PC: GET RESULTS: TSP Control: Fabric Filter Diagram

Each result is described briefly below:

•Area 1: Flue Gas Entering Filter:

•Temperature In: Temperature of the flue gas entering the fabric filter. This is determined by the flue gas outlet temperature of the module upstream of the fabric filter (e.g., the air preheater).

•Flue Gas In: Volumetric flow rate of the flue gas entering the fabric filter, based on the flue gas inlet temperature and atmospheric pressure.

•Fly Ash In: Total solids mass flow rate in the flue gas entering the fabric filter. This is determined by the solids exiting the module upstream of the fabric filter (e.g., the air preheater).

•Mercury In: Total mass of mercury entering the fabric filter. The value is a sum of all the forms of mercury (elemental, oxidized, and particulate).

•Area 2: Flue Gas Exiting Filter:

•Temperature Out: Temperature of the flue gas exiting the fabric filter. The model currently does not alter this temperature through the fabric filter.

•Flue Gas Out: Volumetric flow rate of the flue gas exiting the fabric filter, based on the flue gas exit temperature and atmospheric pressure.

•Fly Ash Out: Total solids mass flow rate in the flue gas exiting the fabric filter. This is a function of the ash content of the inlet flue gas and the particulate removal efficiency performance parameter .

•Mercury Out: Total mass of mercury exiting the fabric filter. The value is a sum of all the forms of mercury (elemental, oxidized, and particulate).

•Area 3: Fabric Filter Performance:

•Ash Removal: Ash removal efficiency of the fabric filter. This is a function of the ash emission constraint and the inlet ash mass flow rate.

•SO3 Removal: Percent of SO3 in the flue gas removed from the fabric filter. The SO3 is assumed to combine with H2O and leave with the ash solids as a sulfate (in the form of H2SO4).

•Mercury Removal: Percent of the total mercury removed from the fabric filter. The value reflects a weighted average based on the particular species of mercury present (elemental, oxidized, and particulate).

•Area 4: Collected Fly Ash:

•4a: Dry Ash: Total mass flow rate of the solids removed from the fabric filter. This is a function of the solids content in the flue gas and the particulate removal efficiency performance parameter . The value is given on a dry basis.

•4b: Sluice Water: Water added to the dry fly ash. This water is added for transportation purposes.

•4a: Wet Ash: Total mass flow rate of the solids removed for waste management. This includes dry fly ash and sluice water. The value is given on a wet basis.

Copyright © 2022-2026 University of Wyoming. All rights reserved. Visit us at https://www.iecm-online.com/