|

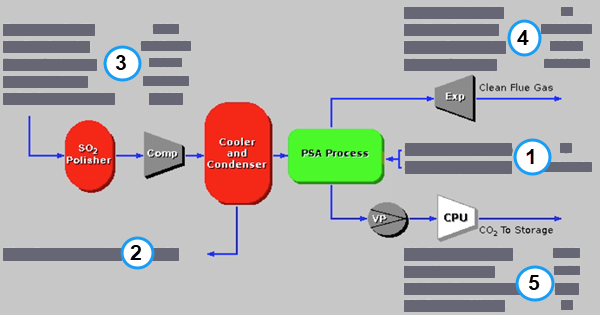

IECM 13.1 User Manual > Modules Included with the IECM > Pulverized Coal (PC) Plant > GET RESULTS > CO2 Capture, Transport & Storage > 1. Solid Sorbents PSA > SolidSorbents PSA Diagram |

|

The Solid Sorbents PSA Diagram result screen shows the major flows into and out of the solid sorbents PSA system:

PC: GET RESULTS: CO2 Capture, Transport & Storage: 1. Solid Sorbents PSA: Solid Sorbents PSA Diagram

The following values are shown:

•Area 1: Sorbent:

•Sorbent Makeup: This is the amount of sorbent makeup required to replace degraded sorbent.

•Sorbent Req.: This is the total amount of sorbent required.

•Area 2: Condenser:

•Water Removed: This is the water removed from the flue gas by the cooler & condenser.

•Area 3: Flue Gas Entering the Solid Sorbents PSA System:

•Temperature In: This is the temperature of the flue gas entering the PSA process.

•Gas Flow In: This is the volumetric flow rate of flue gas entering the PSA process.

•Fly Ash In: This is the total solids mass flow rate in the flue gas entering the PSA process. It is determined by the solids exiting from the module upstream.

•Mercury In: This is the total mass of mercury entering the PSA process. The value is a sum of all the forms of mercury (elemental, oxidized, and particulate).

•NaOH Caustic: This is the NaOH caustic required by the SO2 polisher.

•Area 4: Flue Gas Exiting the Solid Sorbents PSA System:

•Temperature Out: This is the temperature of the flue gas exiting the PSA process.

•Gas Flow Out: This is the volumetric flow rate of the flue gas exiting the PSA process.

•Fly Ash Out: This is the total solids mass flow rate in the flue gas exiting the PSA process.

•Mercury Out: This is the total mass of mercury exiting the ammonia system. The value is a sum of all the forms of mercury (elemental, oxidized, and particulate).

•Area 5: Solid Sorbents PSA System Performance:

•CO2 Captured: This is the flow rate of CO2 in the CO2 product stream.

•Impurities: This is the flow rate of impurities in the CO2 product stream.

•CO2 Pressure: This is the CO2 product pressure as it leaves the compressor. The product stream is compressed and sent through the pipeline system to the configured sequestration system.

•CO2 Removal Eff.: This is the actual removal efficiency of CO2.

Copyright © 2022-2026 University of Wyoming. All rights reserved. Visit us at https://www.iecm-online.com/