|

IECM 13.1 User Manual > Modules Included with the IECM > Pulverized Coal (PC) Plant > GET RESULTS > CO2 Capture, Transport & Storage > 2. Auxiliary Boiler System > Auxiliary Boiler Diagram |

|

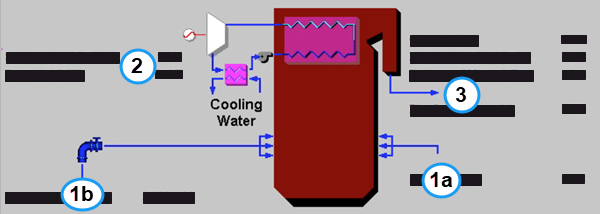

The Auxiliary Boiler Diagram result screen shows the major flows into and out of the auxiliary boiler in PC and NGCC plants:

PC: GET RESULTS: CO2 Control: 2. Auxiliary Boiler System: Auxiliary Boiler Diagram

The following values are shown:

•Area 1: Air and Fuel:

•1a: Air In: The mass flow rate of fresh air is provided. This is the stoichiometric amount of air and excess air as specified on the Auxiliary Boiler Performance input screen .

•1b: Auxiliary Gas In: This is the flow rate of natural gas necessary to provide the heat necessary to provide regeneration heat to the sorbent regenerator.

•Area 2: Steam and Power Generation:

•Steam Supply: This is the total steam energy required by the CO2 regenerator. The steam is supplied to the sorbent regenerator.

•Electricity: Low pressure steam generated by the auxiliary boiler may be used to generate electricity in a steam turbine. This electricity supplements that produced by the base plant.

•Area 3: Flue Gas Exiting Aux. Boiler System:

•CO2: This is the emission rate of carbon dioxide from the auxiliary boiler. It is emitted from a secondary stack.

•Equivalent SO2: This is the emission rate of sulfur dioxide from the auxiliary boiler. It is emitted from a secondary stack.

•Equivalent NO2: This is the emission rate of nitrogen dioxide from the auxiliary boiler. It is emitted from a secondary stack.

•Flue Gas Out: This is the mass flow rate of flue gas exiting the auxiliary boiler. It is emitted from a secondary stack.

Copyright © 2022-2026 University of Wyoming. All rights reserved. Visit us at https://www.iecm-online.com/