|

IECM 13.1 User Manual > Modules Included with the IECM > Pulverized Coal (PC) Plant > GET RESULTS > Water Systems > 1. Water > Makeup Water |

|

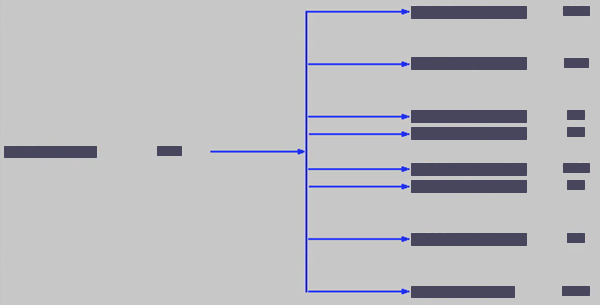

The Makeup Water diagram screen is shown for PC and IGCC plants. The basic format of these diagrams is:

Format of a Makeup Water Diagram

The left side of the diagram contains a single value:

•Plant Inlet: This is the total amount of makeup water required by the plant.

The right side of the diagram gives a breakdown of the makeup water required by various parts of the plant. PC plants show the following values as needed:

•Boiler Makeup: This is the amount of makeup water for the main steam cycle to supplement boiler blowdown and miscellaneous steam losses, which mainly depends on the boiler blowdown rate.

•Cool. Makeup: This is the amount of makeup water for the cooling system. There is no makeup water required for once through and air cooled condenser systems. For the wet cooling tower, the makeup water is required to supplement the evaporation, blowdown and drift losses.

•Bot. Ash Sluice: This is the amount of makeup water used for sluicing bottom ash that is collected at the bottom of the boiler. In a wet sluicing system, bottom ash is sluiced with water and transported to a bottom ash pond where the ash settles in the pond. There may be no need of makeup water to sluice bottom ash as the blowdown from the wet tower and bottom ash pond overflow can be reused as sluice water.

•CS-ESP or FF Sluice: This is the amount of makeup water used for sluicing fly ash that is entrained in the flue gas and removed by air pollution control system equipment such as ESP or fabric filter. There may be no need of makeup water to sluice fly ash as the blowdown from the wet tower and bottom ash pond overflow can be reused as sluice water.

•SCR Makeup: This is the amount of makeup water required for the hot-side SCR.

•SNCR Makeup: This is the amount of makeup water required for in-furnace NOx control.

•FGD or SD Makeup: This is the amount of makeup water needed to replace the evaporated water in the reagent sluice circulation stream.

•CCS Proc. Makeup: This is the amount of process makeup water needed for the CCS system.

•CCS Cool. Makeup: This is the amount of cooling makeup water needed for the CCS system.

Currently, the following CCS systems in PC plants require makeup water:

The right side of the diagram is much simple for IGCC plants. The following values are shown:

•Process: This is the amount of makeup water required for everything except the cooling system.

•Cooling: This is the amount of makeup water required for the cooling system.

Copyright © 2022-2026 University of Wyoming. All rights reserved. Visit us at https://www.iecm-online.com/