|

IECM 13.1 User Manual > Modules Included with the IECM > Pulverized Coal (PC) Plant > GET RESULTS > SO2 Control > Spray Dryer > Spray Dryer Diagram |

|

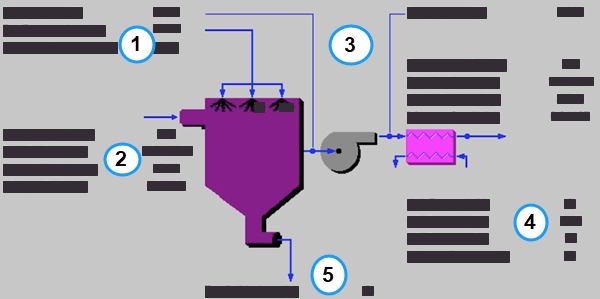

The Spray Dryer Diagram result screen shows the major flows into and out of the Lime Spray Dryer SO2 control technology:

PC: GET RESULTS: SO2 Control: Spray Dryer Diagram

Each result is described briefly below:

•Area 1: Reagent & Makeup Water:

•Dry Reagent: The total mass flow rate of lime injected into the scrubber. This is a function of the SO2 Removal Efficiency, the Reagent Purity and the Reagent Stoichiometry (all performance input parameters ). The reagent is assumed to be dry.

•Makeup Water: This is the amount of water needed to replace water evaporated in the scrubber.

•Area 2: Flue Gas Entering Dryer:

•Temperature In: Temperature of the flue gas entering the scrubber. This is determined by the flue gas outlet temperature of the module upstream of the scrubber (e.g., a particulate removal technology).

•Flue Gas In: Volumetric flow rate of flue gas entering the scrubber, based on the flue gas temperature entering the scrubber and atmospheric pressure.

•Fly Ash In: Total solids mass flow rate in the flue gas entering the scrubber. This is determined by the solids exiting from the module upstream of the scrubber (e.g., a particulate removal technology).

•Mercury In: Total mass of mercury entering the scrubber. The value is a sum of all the forms of mercury (elemental, oxidized, and particulate).

•Area 3: Flue Gas Exiting Dryer:

•Temperature: Temperature of the flue gas immediately after exiting the scrubber. This is a function of saturation temperature, and the flue gas component concentrations. This temperature is used to determine the flue gas bypass required.

•Temperature: Temperature of the flue gas immediately after exiting the induced draft fan. This is a function of flue gas temperature exiting the scrubber, the flue gas bypass and the Temperature Rise Across ID Fan performance parameter .

•Temperature Out: Temperature of the flue gas immediately after exiting the reheater. This is determined by the Gas Temperature Exiting Reheater performance parameter .

•Flue Gas Out: Volumetric flow rate of the flue gas exiting the reheater, based on the flue gas temperature exiting the scrubber and atmospheric pressure.

•Solids Out: Total solids mass flow rate in the flue gas exiting the reheater. This is a function of the Particulate Removal Efficiency performance parameter .

•Mercury Out: Total mass of mercury exiting the scrubber after the reheater. The value is a sum of all the forms of mercury (elemental, oxidized, and particulate).

•Area 4: Spray Dryer Performance:

•Ash Removal: Actual particulate removal efficiency in the scrubber. This is set by the Particulate Removal Efficiency performance parameter .

•SO2 Removal: Actual removal efficiency of SO2 in the scrubber. This is a function of the maximum removal efficiency ( scrubber performance parameter ) and the emission constraint for SO2 ( emission constraints input parameter ). It is possible that the scrubber may over or under-comply with the emission constraint.

•SO3 Removal: Percent of SO3 in the flue gas removed from the scrubber. The SO3 is assumed to combine with H2O and leave with the ash solids or sluice water as a sulfate (in the form of H2SO4).

•Mercury Removal: Percent of the total mercury removed from the scrubber. The value reflects a weighted average based on the particular species of mercury present (elemental, oxidized, and particulate).

•Area 5: Collected Solids:

•Dry Solids: Total solids mass flow rate of solids removed from the scrubber. This is a function of the solids content in the flue gas and the Particulate Removal Efficiency of the scrubber. The solids are assumed to be dry.

Copyright © 2022-2026 University of Wyoming. All rights reserved. Visit us at https://www.iecm-online.com/