|

IECM 13.1 User Manual > Modules Included with the IECM > Pulverized Coal (PC) Plant > GET RESULTS > CO2 Capture, Transport & Storage > 1. Amine System > Amine System Diagram |

|

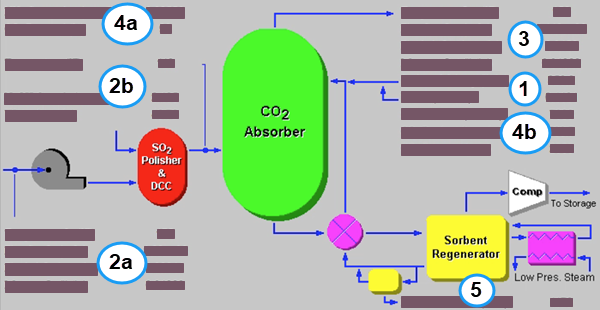

The Amine System Diagram result screen shows the major flows into and out of the amine CO2 control system in PC and NGCC plants:

PC: GET RESULTS: CO2 Capture, Transport & Storage: 1. Amine System: Amine System Diagram

The following values are shown:

•Area 1: Reagent:

•Sorbent Makeup: (N/A for Cansolv .) The mass flow rate of fresh sorbent needed to replace the amount used in the process.

•Water: This is the flow rate of water that is used to mix with the Sorbent Makeup.

•Area 2: Flue Gas Entering Amine System:

•2a:

•Temperature In: Temperature of the flue gas entering the amine system area, prior to any processing. This is determined by the flue gas outlet temperature of the process area upstream.

•Flue Gas In: Volumetric flow rate of flue gas entering the amine system.

•Fly Ash In: Total solids mass flow rate in the flue gas entering the Amine System. This is determined by the solids exiting from the module upstream.

•Mercury In: Total mass of mercury entering the amine system. The value is a sum of all the forms of mercury (elemental, oxidized, and particulate).

•2b:

•Temperature: Temperature of the flue gas entering the amine scrubber system.

•NaOH Caustic: This is the amount of NaOH Caustic required for the SO2 polisher.

•Water: This is the flow rate of water into the Direct Contact Cooler.

•Area 3: Flue Gas Exiting Amine System:

•Temperature Out: Temperature of the flue gas exiting the amine scrubber system.

•Flue Gas Out: Volumetric flow rate of the flue gas exiting the amine scrubber.

•Fly Ash Out: Total solids mass flow rate in the flue gas exiting the amine scrubber.

•Mercury Out: Total mass of mercury exiting the amine scrubber. The value is a sum of all the forms of mercury (elemental, oxidized, and particulate).

•Area 4: Amine System Performance:

•4a:

•NH3 Generation: The flow rate of ammonia by product produced in the amine scrubbing process.

•CO2 Removal: Actual removal efficiency of CO2 in the amine scrubber.

•4b:

•Sorbent Circ.: (Not shown for Cansolv .) The flow rate of the sorbent through the amine scrubber system.

•CO2 Product: Actual amount of CO2 produced as a result of the amine scrubbing.

•CO2 Pressure: Compressed CO2 product pressure. The product stream is compressed and sent through the pipeline system to the configured sequestration system.

•Area 5: Collected Solids:

•Reclaimer Waste: (Not shown for Cansolv .) Total solids mass flow rate of solids removed from the amine scrubber.

Copyright © 2022-2026 University of Wyoming. All rights reserved. Visit us at https://www.iecm-online.com/