UW Engineering Professor Receives Grant for Novel Approaches to Soft 3D Printed Materials

Published August 15, 2025

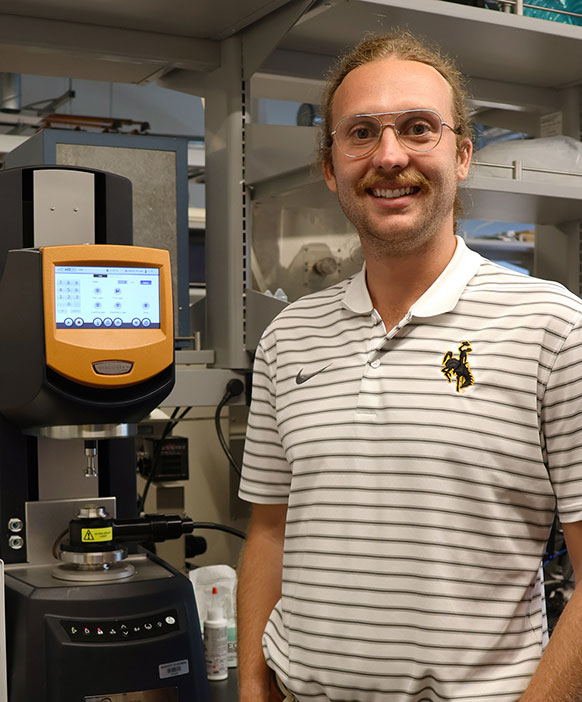

Daniel Rau, an assistant professor in UW’s Department of Mechanical Engineering, studies methods for improving 3D printing of soft materials. (UW Photo)

3D printing technologies have exploded in capacity in recent years, gaining popularity for both commercial and home use. However, according to Daniel Rau, a University of Wyoming assistant professor of mechanical engineering, they still suffer from a critical shortcoming: 3D printers currently can produce only hard, brittle plastic items.

Useful as it may be to quickly produce household items, toys and car parts to specifications, however, current 3D printing technologies leave an area of great potential untapped: how to make things soft. Rau’s Additive Manufacturing Lab (RAM Lab) aims to close this gap, thanks to a grant from the National Science Foundation (NSF) for engineering research initiation. This specific NSF grant program aims to help new university faculty kick-start their research programs by funding research expenses and student stipends.

Such support proves essential for helping “to get young people like me going and have successful careers,” Rau says, expressing gratitude to the NSF.

Rau, who joined UW’s Department of Mechanical Engineering in fall 2024, will use his $198,932 award to study why current additive manufacturing processes -- the technical name for 3D printing -- produce warped blobs rather than stable, functional products when attempting to print elastomers, which are more flexible, stretchy or rubber-like materials. His research project is titled “Improving the Vat Photopolymerization 3D-Printing of Soft Elastomers Through a Deeper Understanding of Process Dynamics.”

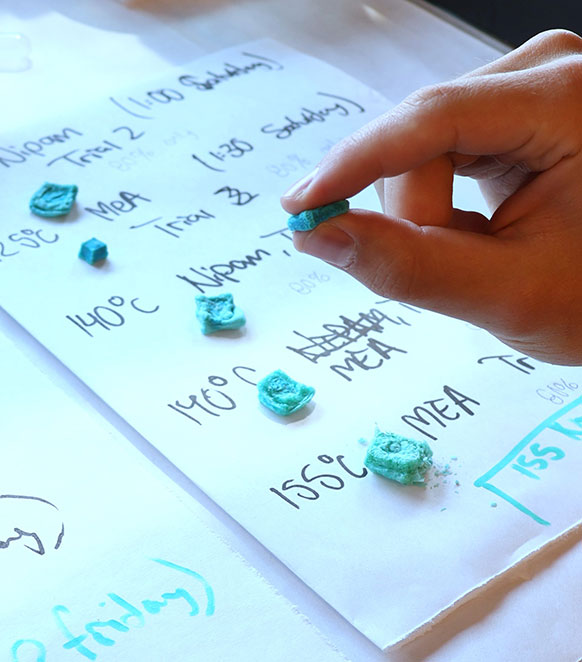

“This particular additive manufacturing process deals with a really unique class of materials called photopolymers. They're liquid; you hit them with UV light -- think of really strong sunlight -- and they solidify,” Rau says. “But we have a lot of questions on how that exact transition from liquid to solid occurs. Our materials are very soft, and we think there are some unique things going on, so we’re making measurements to look at that.”

Undergraduate student Holden Eigenberger, of Cheyenne, demonstrates the compressibility of a test sample of soft 3D printed material in Daniel Rau’s Additive Manufacturing Lab at UW. (UW Photo)

Understanding the printing process better will require the employment of two novel approaches -- photorheology and X-ray photon correlation spectroscopy (XPCS) -- to study the adhesion process during curing of the photopolymers on a much deeper level. For the latter experimental process, Rau is collaborating with a team at the Brookhaven National Laboratory on Long Island, N.Y. Rau will use Brookhaven’s 2.5-kilometer synchrotron to accelerate X-ray beams onto printed materials to get a very localized understanding of what is happening during the curing process.

With the insights gained from these experiments, Rau intends to produce a cookbook of sorts with recipes to help tailor manufacturing processes for soft materials. Successfully mobilizing this technology could have a huge impact on daily living, especially in the biomedical industry.

“There's a lot of potential. You know, the human body is very soft. So, there are a lot of things the human body likes soft, whether it’s implants or wearable devices,” Rau says. “Or, say you want a more comfortable pair of running shoes. Say you want a better football helmet that can protect against concussions. With 3D printing, we can create these really cool geometries and trusses so that, actually, the geometry absorbs some of the impacts.

“Between what’s enabled by the 3D printing and what’s enabled by the material, we think we could get really, really good performance. So that’s where I think the transformative potential comes in.”

You can read more about this grant here: www.nsf.gov/awardsearch/showAward?AWD_ID=2502245&HistoricalAwards=false.