Our Research Impact

Our work has critical applications in enhanced oil recovery (EOR), underground hydrogen storage, and geological carbon dioxide storage. We aim to address oil recovery challenges in both conventional and unconventional reservoirs and enhance the understanding of H2 and CO2 injection, storage, and removal from geologic formations.

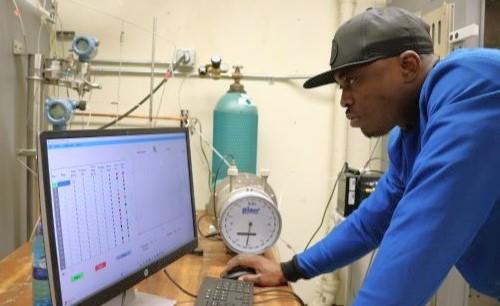

Our current research investigates flow-pressure interactions in the Mowry shale of the Powder River Basin. The generated experimental data are crucial for predicting flow, optimizing storage and recovery, ensuring safety, supporting modeling, designing injection/extraction strategies, and understanding recovery techniques.

Lab Instrumentation

| High-Pressure High-Temperature Multiphase Core Flooding System (HPHT-MCFS) | |

|

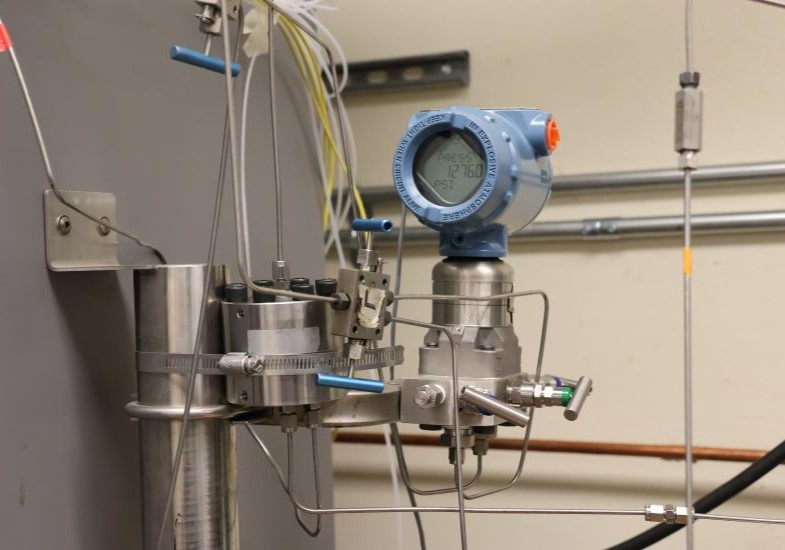

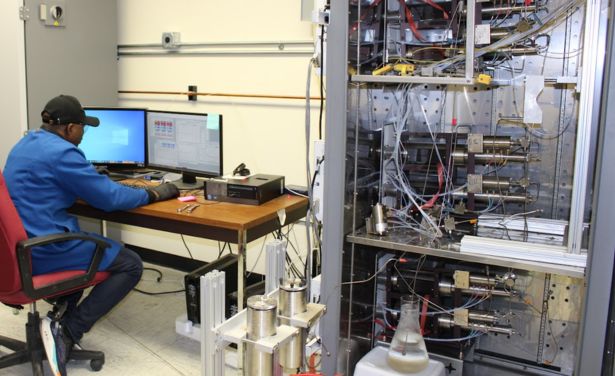

Housed in a 6.5 feet by 3 feet SHEL LAB oven, the HPHT-MCFS are capable of operating at temperatures between 25oC and 260oC. These experimental set ups are used to investiagate basic reservoir rock properties such as porosity, and both relative and absolute permiability. The oil unit has the capability to study water flooding and EOR research (e.g., low salinity water, surfactant, and nanoparticle injections).

|

|

| The Oil Unit is equipped with the following accessories: | |

|

|

| The Gas Unit is similar except that it contains: | |

|

|