State-of-the-Art Labs

Published January 21, 2026

The University of Wyoming is home to numerous cutting-edge laboratories — such as the five highlighted here — that give students the opportunity to use their classroom knowledge, gain industry experience and conduct real-world research.

Recent graduate Kimberly Carter conducts research in the new Course-Based Undergraduate Research Experiences lab in the Science Initiative Building.

Course-Based Undergraduate Research Experiences (CURE) Lab

Most students who participate in undergraduate research name it as one of their most

impactful university experiences. However, not every undergraduate can take part in

longer-term research programs due to time, funding or limited spots. Enter the new

CURE lab on the fourth floor of the Science Initiative Building, which will give students

in science courses the chance to conduct short-term novel research. The flexible lab

space can be adjusted for various courses and projects. “Undergraduate research is

a well-recognized best practice in science,” says Science Initiative Course Based

Undergraduate Research Coordinator Ami Wangeline. “Students are trying to learn the

scientific process, so they need to experience it.” Wangeline will work with instructors

to design the CURE curriculum and then coordinate the lab space to meet the needs

of the course and student projects.

Graduate student Cindy Agyemang works in the Science Initiative Building’s Richard and Marilyn Lynch Multidisciplinary Advanced Stimulation Lab. (Photo by Janna Urschel)

Richard and Marilyn Lynch Multidisciplinary Advanced Stimulation Lab

The new Richard and Marilyn Lynch Multidisciplinary Advanced Stimulation Lab is located on the first floor of the Science Initiative Building and features 5,000 square feet and more than $2 million worth of equipment focused on improving oil and gas recovery. Energy and Petroleum Engineering Department Head Soheil Saraji explains that currently only about 10 percent of oil is extracted in the primary stage, making even a 5-percent improvement extremely valuable to industry partners. Industry will sponsor student interns within the lab, and it will welcome visiting industry experts and academics as well as 30 doctoral students and undergraduate researchers. “The lab is supported by the Department of Petroleum Engineering and the School of Energy Resources,” Saraji says. “We brought in a diverse set of expertise from geomechanics, fluid dynamics, drilling and well completion, petrophysics and artificial intelligence, so it is truly a multidisciplinary lab.”

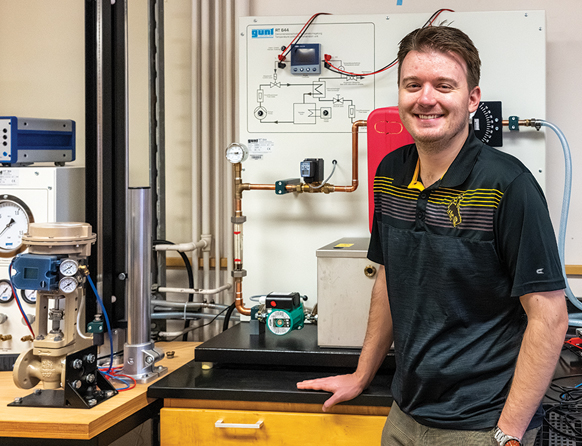

Ian Hammontree, the coordinator for UW’s process controls minor, helps students utilize the Process Control Simulation Lab.

Process Control Simulation Laboratory

The demand for qualified process control employees outpaces the availability, which

led the Department of Chemical and Biomedical Engineering to develop the process control

and instrumentation minor in 2018 and to open the Process Control Simulation Laboratory

in 2021 with seed funding from Genesis Alkali. This past fall, HF Sinclair made an

additional investment, allowing the lab to expand its hardware and software. “Students

can now experience a real-world hands-on learning environment with devices, data and

situations congruent with an industrial environment following industrial standards,”

says Assistant Lecturer Ian Hammontree. “We utilize plant data and simulations from

currently operating plants to give our students the opportunity to see what it’s like

in a real control room, which is an invaluable experience.” The department also offers

a process control and instrumentation minor. Read more in the upcoming spring issue

of UWyo Magazine.

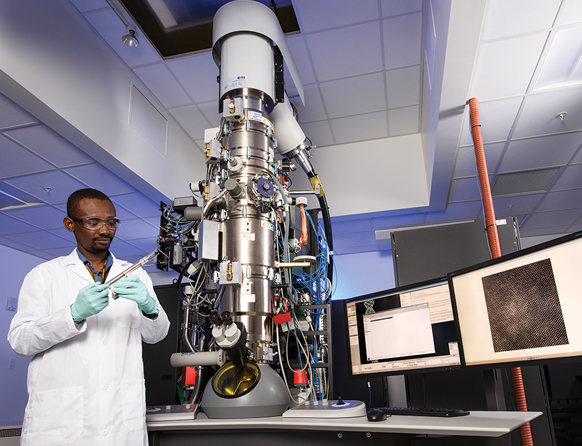

Former graduate student Samuel Afari works in the Center of Innovation for Flow Through Porous Media in the High Bay Research Facility.

Center of Innovation for Flow Through Porous Media (COIFPM)

The Center of Innovation for Flow Through Porous Media (COIFPM) is one of the world’s

largest and most advanced research facilities of its kind. It is recognized as a global

leader in the research and development of novel technologies in the area of flow through

porous media and its applications in, for instance, oil and gas recovery, geological

carbon sequestration, hydrogen geo-storage and aquifer remediation. Established in

2017, COIFPM offers unparalleled integrated experimental and computational capabilities

across the atomic, nano, micro and macro scales. These capabilities, when coupled

with the center’s unmatched capacity, allow researchers to conduct numerous multifaceted

studies concurrently, generating both fundamental insights and practical innovations.

COIFPM serves as a catalyst for innovation, sustainability and economic growth in

Wyoming and across the globe. It is a core component of UW’s Tier-1 Engineering Initiative

and represents a transformational research hub with broad impact across science, technology

and industry.

WWAMI medical student Easton Couch treats standardized patient volunteers in the new center. (Photo by Todd Guth)

Simulation and Standardized Patient Center

The College of Health Sciences recently launched a new state-of-the-art Simulation

and Standardized Patient Center at the Mountain View Medical Center in Laramie. It

is designed to immerse students in realistic team-based clinical scenarios that mirror

the challenges and dynamics of today’s health-care environments. “The center promotes

interprofessional education by bringing together students from nursing, pharmacy,

social work, communication disorders, kinesiology and other health programs,” says

Dean Patrick Hardigan. “Through high-fidelity simulation and trained standardized

patients, students will develop essential clinical communication and decision-making

skills in a safe controlled environment.” The space includes ultrasound equipment,

six observation-style treatment rooms, feedback and recording technology and virtual

reality technology. In addition to student learning, the space will be used for research

and continuing-education courses.