RELIABILITY PREDICTION IN COMPOSTIE STRUCTURES: A DEFECT SENSITIVE MULTISCALE STOCHASTIC MODEL

Inability to predict composite reliability has led many manufacturers to abandon the use of composites or resort to severe overdesign. Composite reliability is driven by the presence of defects in the composite microstructure. State-of-the-art composite failure prediction assumes average composite behavior, which cannot predict the effect of defects. Our essential hypothesis is that real composite microstructures can be represented as a stochastic combination of idealized microstructures, which can incorporate realistic constituent-level physics for reliability prediction. Finite element studies are underway to determine an appropriate methodology for computing the stochastic parameters linking the idealized microstructures to the random microstructure. Ultimately, this approach will be integrated into existing commercial finite element codes to simulate composite structure reliability with known defect distribution.

BIO-INSPIRED COMPOSTIE MICROSTRUCTURE DESIGN

IMAGE: Coral pattern generated by Turing model.

Many unique microstructures are observed in nature that are optimal for their specific applications, such as sea shells and bone. These structures have served as a source of inspiration for revolutionary synthetic materials. However, sythetically reproducing these materials has proven difficult, due to the intricacies of the structures, specifically the different length scales involved ranging from molecular to macroscopic. Instead of attempting to replicate these materials (biomimetics), our group is using bio-inspired pattern generation algorithms coupled with machine learning to search for new application-specific topologies inspired from natural processes. Our most recent work involves the use of reaction-diffusion pattern generation algorithms in conjunction with finite element analysis. The goal of this research is to broaden our horizons past traditional engineering procedures in order to develop new composite materials.

MICROCRACKING IN POROUS HIGH-TEMPERATURE CERAMICS

IMAGE: Optical micrograph of a porous ceramic (cordierite).

Porous ceramics are an important class of materials for environmental control technologies, in particular, diesel particulate filters (DPFs) and catalytic converters. These applications require the ceramic to function through a temperature range of more than 1200 C. Changes in temperature of this magnitude lead to severe microcracking, which can be healed at high temperature. Thus, the microcracking behavior is history dependent. The goal of this project is to develop a mechanistically sound macroscopic model to predict the elastic and thermal properties of the porous ceramic as a function of temperature. As a tool to study microcracking in porous ceramics, finite element models are constructed that approximate relevant microstructural features of the ceramic. These models are used to carefully study the relationship between local material behavior and macroscopic ceramic behavior. The most recent work in this area has been the development of a constitutive model that is capable of predicting cracking due to combined thermal and mechanical loads.

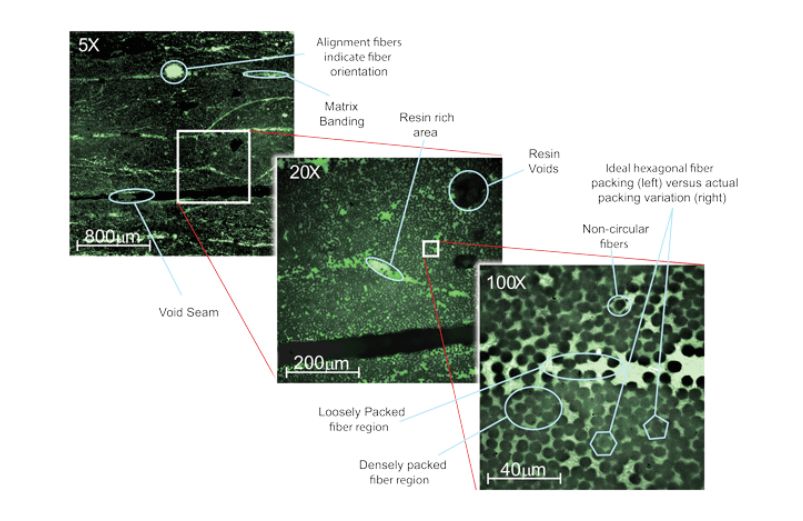

LINKING COMPOSITE PROCESSING VARIATION WITH MICROSTRUCTURAL AND PROPERTY VARIATION

The above two research topics, reliability and lifetime prediction, require fundamental understanding of why material properties vary. Our group uses a combination of experiment and simulation to investigate the relationship between processing and microstructure, and between microstructure and properties. We use optical microscopy under epi-fluorescence and dark field to characterize microstructures and observe their failure in situ using a custom-built micro-tester. Unlike the majority of studies, we are not only interested in examining the effect of microstructure on average property values but also its relationship to property distributions. These distributions are used to inform the stochastic physics-based models that we are working to develop.

IMAGE: Microstructural variations at multiple length scales in a carbon/epoxy unidirectional composite manufactured for a wind turbine blade.

Dislocation Structure Engineering

Recent theoretical work has suggested that dislocation structures in thin films may be strongly influenced by load history, not simply final load. In particular, the types of interactions that occur in films and that drive the evolution of the dislocation structure are biased by the applied film stress relative to the thickness-dependent channeling stress in the film. Thus, structure of the dislocations may be engineered via careful control of film stress during the growth of the film. This is of critical importance, as the presence of particular dislocation structures is the primary impediment to higher efficiencies in high energy solar cells. The goal of this project is to develop a 2.5D dislocation dynamics simulation tool, validated using 3D simulation, to predict and optimize dislocation structures in thin film multijunction solar cells.